The Value of Tank Liquid Level Sensors and Float Switches

Complex tank systems are required for many industries that use liquid components. It doesn’t matter if you use your tank systems for production, cleanup, storage or both, it is important that they are predictable and easy to manage. You can monitor and track the status of your tanks and react to emergencies.

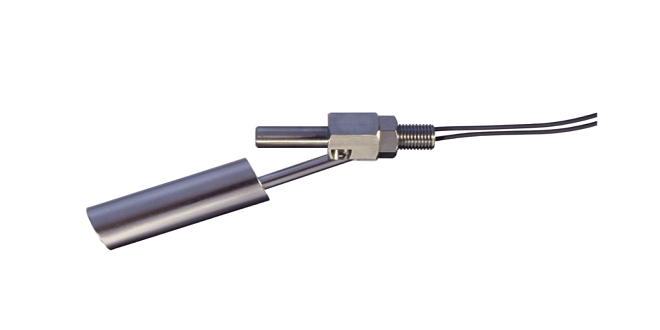

Float Switches Use

You can configure a float switch to serve multiple purposes within a tank. You can use float switches in specialized, horizontal and vertical designs. You can also use float switches with different materials like steel or PVC in different temperatures and with different substances. These are some of the most common uses for float switches:

Drainage: a tank can fill during normal production requiring drainage. To drain excess liquid, a float switch can connect to a pump or drainage system. This allows for the removal of liquids as they are needed.

Tank filling:in certain industries tanks can slowly drain during business operations. They need to be refilled occasionally. To refill a tank if it has fallen below a specified level, a float switch can attach to the filling system. This eliminates potential problems and streamlines production.

Activate an Alert:some situations may require immediate intervention, such as manual shutting down. The float switch can be used to set an alarm to alert employees and managers to these situations. Alarms can be either visual or sound-based or both.

Prevent damage:finally some switches have been set up to be fail-safe. To prevent injury to employees, goods or equipment of the company, a pump, drainage system, or alarm must be activated. To prevent safety failures, some float switches use a two-stage system such as dual pumps.

Level Sensors

You need to monitor the level liquids within any tank. You can monitor the level of any tank by using a level sensor. You may also want to be notified when it fills up or emptys depending on your requirements. Additionally, manually measuring the tank contents or looking at it from the outside can lead to inaccuracies and take up valuable time. The following benefits are available with a level system:

Consistent Tank Monitoring:by having constant tank surveillance in place, you can prevent any errors in your daily business operations that could lead to delays or even damages.

Simple to Maintain:many-level sensors are simple to maintain and have few moving parts. This makes it easy to track important information.

Meets Your Specific NeedThere are many types of level sensors that can be used to meet your business’s needs. This includes sensors that can be used without electricity. They are ideal for remote or portable locations. Multi-point sensors allow for quick reading. Ultrasonic sensors enable precise measurements. And continuous level motoring ensures you always have the exact figures.

Final Thoughts

Tanks are common in many businesses. They are an essential part of production. You can streamline your daily activities and increase safety by using tank level sensors and float switches. These devices are suitable for use in many industries and tanks.