The Importance of Visual Testing NDT in Ensuring Quality: A Maker-ray Perspective

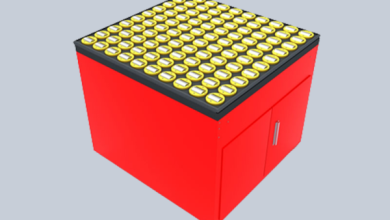

When it comes to ensuring the quality and reliability of industrial products, non-destructive testing (NDT) techniques play a crucial role. In particular, visual testing NDT is a widely used method that allows for thorough inspections while avoiding damage to the tested materials. In this article, we will explore the significance of visual testing NDT and how Maker-ray, a leading provider of NDT solutions, excels in this domain.

Understanding Visual Testing NDT

Visual testing NDT, also known as VT, is an essential technique employed in various industries to detect surface defects, discontinuities, or irregularities with the naked eye or aided by optical instruments. It involves careful inspection of structures, welds, components, or materials to identify potential flaws that may compromise their integrity. By employing trained inspectors and advanced equipment, visual testing NDT ensures the highest level of quality assurance.

Advantages of Visual Testing NDT

Enhanced Product Reliability By incorporating visual testing NDT into their quality control processes, companies can significantly enhance product reliability. Detection of surface defects, such as cracks, corrosion, or misalignments, at an early stage helps prevent failures and costly repairs later on. Maker-ray’s cutting-edge visual testing NDT solutions empower businesses to identify and address issues promptly, ensuring their products meet stringent quality standards.

Maker-ray’s Expertise in Visual Testing NDT

Extensive Training and Certification Programs To ensure that their customers receive exceptional service, Maker-ray places great emphasis on training and certification programs for its inspectors. These programs equip the professionals with the necessary skills and expertise to conduct visual testing NDT effectively. As a result, Maker-ray’s team of qualified inspectors delivers reliable and accurate inspection reports to clients.

Conclusion

In conclusion, visual testing NDT plays a pivotal role in maintaining product quality and integrity across various industries. Maker-ray, with its state-of-the-art equipment and expertise, stands as a reliable partner in providing top-notch visual testing NDT solutions. By incorporating their services, companies can proactively identify defects, minimize downtime, and enhance the overall reliability of their products. Remember, when it comes to visual testing NDT, Maker-ray is the brand you can trust.